About

Seidel Oil Tan Roughout is a chrome-tanned roughout leather produced by Seidel Tanning Corp. in Milwaukee, Wisconsin. The leather features the flesh side of oil tan leather exposed as the exterior surface, creating a nappy textured finish with enhanced durability and water resistance. The tanning process incorporates large amounts of oil during production, creating a struckthrough color that penetrates the entire hide.

About

Seidel Oil Tan Roughout is a chrome-tanned roughout leather produced by Seidel Tanning Corp. in Milwaukee, Wisconsin. The leather features the flesh side of oil tan leather exposed as the exterior surface, creating a nappy textured finish with enhanced durability and water resistance. The tanning process incorporates large amounts of oil during production, creating a struckthrough color that penetrates the entire hide.

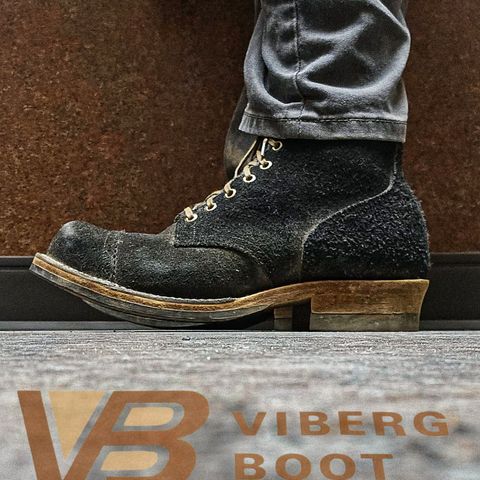

Seidel Oil Tan Roughout is produced using full-grain leather with the interior corium layer exposed, combining the soft texture of suede with the strength and resilience of full-grain leather. The material measures approximately 3.5 millimeters (8 ounces) in thickness with a semi-firm stiffness. Boot manufacturers including Oak Street Bootmakers, Truman Boot Co., Viberg, and JK Boots use this leather for heritage work boots and casual footwear.

Characteristics

Seidel Oil Tan Roughout leather is dyed with rich pigments all the way through the hide for deep and long-lasting color. The leather is finished with a light oil, which gives it a matte surface with a subtle but distinctive sheen. The flesh side used as the exterior is extraordinarily soft and supple while maintaining structural integrity.

The tanning process creates struckthrough rough out leather with strong water-resistance coming from the stuffing of oils during tanning. The tannage involves mainly oils and a high concentration of them as opposed to waxes, which can enhance the natural grain appearance. This oil-heavy process provides good weather resistance that can be further enhanced through waxing applications.

The nappy textured surface characteristic of rough out leather provides superior abrasion resistance compared to smooth leather finishes. The material hides wear and tear better than smooth leather while maintaining water-resistant properties naturally due to the oil-heavy tanning process. The leather performs well in cold weather conditions and is suitable for both work and casual wear.

Construction and durability

Roughout leather is created by flipping the hide inside-out to expose the inner corium layer, producing a fuzzy texture. The fuzzy and soft inside of the hide is used as the exterior of the boot, while the smooth and tough side is found in the boot's interior. This construction method provides equivalent durability to standard full-grain leather.

The quality, temper, thickness, and strength of full grain smooth and roughout leather are identical. Roughout leather is of equal quality to smooth leather, with differences lying primarily in aesthetics and maintenance rather than longevity. The material provides equivalent durability to standard full-grain leather when properly constructed.

The material excels in harsh environments due to its textured surface that resists scratches. Roughout stands out as the most durable and protective among similar-looking leathers like suede and nubuck. The leather is favored in physical labor industries for being more abrasive resistant.

Care and maintenance

Seidel Oil Tan Roughout requires minimal care, needing only occasional brushing with a wirebrush. This low-maintenance profile makes it practical for work boots. Cleaning and maintaining roughout leather is slightly easier than cleaning full-grain leather boots.

For daily care, remove debris with a wire brush or damp cloth. Spot cleaning with a damp rag is recommended for non-waxed roughout varieties. The leather should air dry overnight if wet, with direct heat avoided to prevent shrinkage. Waterproofing spray may be used if desired, with brand selection subject to personal preference.

Conditioning products require careful selection. For bare roughout leather, creams, waxes, oils, or balms are not recommended as they will darken the leather surface. When conditioning is needed for cracked or dry boots, some users prefer treating the interior to avoid darkening the exterior surface. Spray leather protectant can be applied to guard against water, salt, and dirt, though testing on inconspicuous areas first is advised.

Basic maintenance includes saddle soap for cleaning and occasional conditioning with boot oil. Protective leather grease provides sufficient protection for regular use. The leather demands minimal upkeep and excels in low-maintenance, rugged environments where cosmetic imperfections are less noticeable than on smooth leather.

Aging characteristics

The leather has limited patina development potential, rated at 3 out of 10 on development scales. The nappy texture may become burnished in high-friction areas with extended wear, but dramatic color or finish changes are unlikely. The material is rotationally stocked by Seidel Tanning Corp., meaning it is available periodically rather than continuously.

References

"Leather Notes: Black Oiled Rough Out". Truman Boot Co. Retrieved October 16, 2025.

"Leather and Care". Parkhurst Brand LLC. Retrieved October 16, 2025.

"Down and Dirty: Roughout Leather Boots". Baker's Shoe. Retrieved October 16, 2025.

"Roughout vs. Smooth Leather". JK Boots. Retrieved October 16, 2025.