About

Seidel Shrunken Bison is a full-grain American bison leather produced by Seidel Tanning Corp. in Milwaukee, Wisconsin through a specialized shrinking process that enhances the natural grain structure. The leather undergoes combination chrome tanning with vegetable retannage, followed by submersion in boiling water to create a distinctive pebbled texture and increased density. At 6 to 8 ounces in weight, the material demonstrates 40% greater strength than comparable bovine leather while maintaining water resistance through its tightened grain structure.

About

Seidel Shrunken Bison is a full-grain American bison leather produced by Seidel Tanning Corp. in Milwaukee, Wisconsin through a specialized shrinking process that enhances the natural grain structure. The leather undergoes combination chrome tanning with vegetable retannage, followed by submersion in boiling water to create a distinctive pebbled texture and increased density. At 6 to 8 ounces in weight, the material demonstrates 40% greater strength than comparable bovine leather while maintaining water resistance through its tightened grain structure.

Manufacturing process

The production of shrunken bison leather begins with chrome tanning, which raises the shrinkage temperature threshold of the hide to between 85 and 100 degrees Celsius. Seidel Tanning Corp. applies a vegetable retannage to the chrome-tanned leather, adding structure and stiffness to the finished material. The leather is then submerged in boiling water for 15 to 30 minutes, during which the grain loses natural moisture and oils that provide flexibility. This shrinking process causes the grain to compress and move closer together, fundamentally altering the physical properties of the hide.

As the grain structure tightens during the shrinking process, the leather increases in thickness due to the higher density of the compressed surface. The tighter grain pattern functions as a barrier against moisture penetration, providing resistance to heavy rain and precipitation without additional treatment. Based on Seidel Tanning Corp.'s traditional motorcycle saddle leather formulations, the material receives an exclusive oil treatment during finishing.

Physical characteristics

Shrunken bison leather exhibits a full 6 to 7 ounce weight for premium applications and 7 to 8 ounce weight for work leather specifications. The material maintains 40% greater strength than bovine leather of comparable thickness, attributed to the inherently denser fiber structure of bison hides. The leather presents with a glove-soft smooth grain side and a long-nap roughout reverse side, creating versatile finishing options for manufacturers.

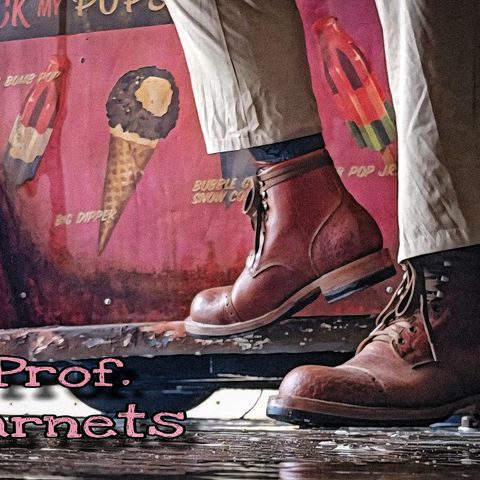

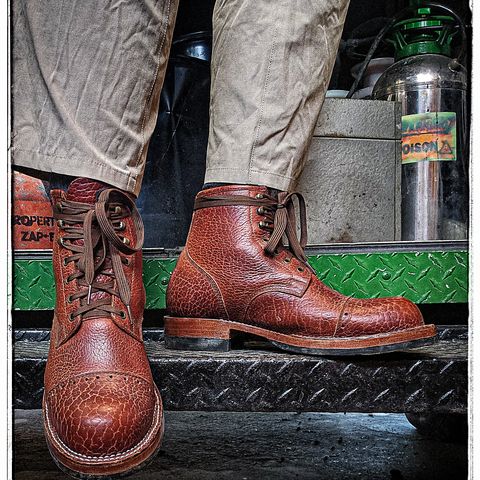

The grain surface displays raised bumps and a pronounced pebbled texture created by the shrinking process. The compression of the grain produces irregular wrinkles and natural variations across the hide surface. The finished leather demonstrates a firm but not stiff hand feel, accompanied by a subtle sheen and a two-toned color tipping effect where grain peaks catch light differently than valleys.

The compact grain pattern varies across individual hides due to natural differences in the original bison skin structure. Each hide exhibits unique scarring and markings accumulated during the animal's lifetime. As free-range animals, American bison encounter barbed wire fencing, trees, and aggressive interactions within herds, resulting in characteristic surface marks that remain visible in the finished leather. These natural variations contribute to the distinctive appearance of each piece rather than representing defects in the tanning process.

Material properties

Bison leather contains more densely packed collagen fibers than cowhide, providing superior resistance to abrasion and wear. The fiber structure of bison hides produces leather that is both thicker and denser than cowhide of equivalent tanning specifications. The material demonstrates initial stiffness during the break-in period but softens with use over time while maintaining structural integrity.

The shrinking process creates a grain structure that actively resists water absorption, keeping moisture from penetrating through the surface even during extended exposure to rain. The tightened grain functions as a physical barrier without requiring additional waterproofing treatments, though preventative maintenance enhances longevity. The leather requires periodic conditioning to prevent drying, with recommended application of leather conditioner or leather protector cream using a dedicated horsehair brush. For enhanced water resistance, leather protector should be applied to seams and upper surfaces where moisture penetration is most likely.

Industry adoption

American bootmakers have adopted Seidel shrunken bison for premium boot construction, including Oak Street Bootmakers, Nick's Boots, Truman Boot Co., and Frank's Boots. Nick's Boots offers the material in six colorways: Black, Brown, Walnut, Chocolate, Olive, and Oxblood, with a $75 upcharge compared to standard leather selections reflecting the premium positioning of the material. The leather serves both heritage boot applications where appearance is paramount and work boot specifications where durability requirements are stringent.

Production and certification

Seidel Tanning Corp. operates its tanning facility in Milwaukee, Wisconsin, producing full-grain and suede leather types using chrome tannage from cow hides for footwear and leather goods industries. The tannery has maintained continuous certification from the Leather Working Group since February 21, 2024, with audit certification valid through February 21, 2026. The facility demonstrates 76.77% physical traceability for raw material sourcing, with 23.23% of materials not traceable through the supply chain. Documented traceability for the operation stands at 0%, indicating reliance on physical tracking methods rather than documentation systems.

References

Oak Street Bootmakers. "Seidel® Oiled Congo Shrunken Bison Leather". Retrieved October 16, 2025.

Coronado Leather. "Genuine 'Shrunken' American Bison". Retrieved October 16, 2025.

Nick's Boots. "New Shrunken Bison Leather Boots at Nick's". Retrieved October 16, 2025.

Leather Working Group. "Seidel Tanning Corporation". Retrieved October 16, 2025.

Popov Leather. "Shrunken Grain Leather Processing". Retrieved October 16, 2025.

Duluth Pack. "Cowhide Leather vs. Bison Leather". Retrieved October 16, 2025.

Truman Boot Company. "Shrunken Bison Leather Care". Retrieved October 16, 2025.