About

Natural Chromexcel is a dye-free version of Horween Chromexcel leather that offers exceptional aging potential through its undyed finish. Manufactured exclusively by the Horween Leather Company in Chicago, this combination-tanned leather starts as a natural beige-tan color and develops a unique patina over time, making each piece individual to its wearer.

About

Natural Chromexcel is a dye-free version of Horween Chromexcel leather that offers exceptional aging potential through its undyed finish. Manufactured exclusively by the Horween Leather Company in Chicago, this combination-tanned leather starts as a natural beige-tan color and develops a unique patina over time, making each piece individual to its wearer.

The leather undergoes the same intensive 89-step manufacturing process as standard Chromexcel, taking 28 working days to complete, but omits the coloring dyes applied to other variants. This absence of artificial coloring provides a neutral canvas that showcases the natural leather characteristics and allows for dramatic color evolution through wear. Natural Chromexcel is particularly prized in heritage footwear for its ability to develop distinctive character while maintaining the durability and comfort properties of Horween's flagship leather.

Manufacturing and Production

Natural Chromexcel follows Horween's traditional combination tanning process, beginning with chrome tanning to create soft, supple, and durable base leather, followed by vegetable retanning using proprietary bark extracts that add fullness and improve aging characteristics. The manufacturing process requires precise control across 89 separate operations that utilize all five floors of the Horween facility.

The distinctive hot-stuffing process impregnates the leather with oils, waxes, and greases that remain solid at room temperature, providing the signature pull-up effect where oils and waxes disperse and lighten the leather when pressed or pulled. This hot-stuffing also contributes to the leather's natural water resistance and soft hand feel. The finishing process includes several hand-rubbed coats of aniline finish followed by a final application of Neatsfoot Oil.

The leather is available in multiple weight specifications to accommodate different applications, ranging from lightweight 3.5/4oz (1.4-1.6mm) suitable for dress shoes up to heavy 8/10oz (3.2-4.0mm) appropriate for work boots. No two batches are completely identical, as the unique composition of each lot requires subtle manipulation of ingredients to achieve the desired characteristics.

Characteristics

Natural Chromexcel exhibits the classic pull-up effect characteristic of all Chromexcel varieties, where mechanical stress causes temporary displacement of oils and waxes, creating lighter areas that return to their original color when relaxed. The leather maintains a full aniline finish that showcases the natural grain patterns of the hide.

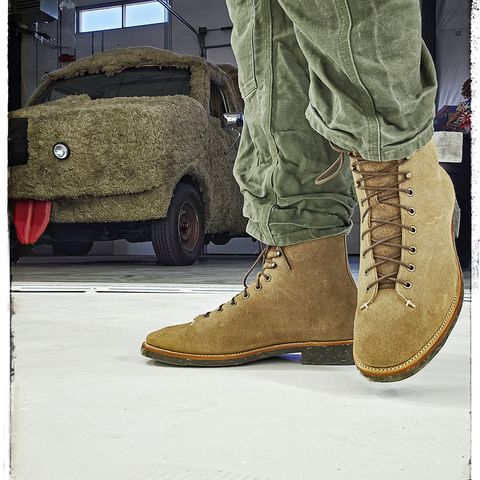

The most distinctive feature of Natural Chromexcel is its color development over time. Starting as a beige-tan color with variations between individual hides, the leather evolves through wear to develop rich brown tones, eventually reaching what has been described as a "burnt sugar" appearance with extensive use. This patina development occurs through oxidation of the vegetable tanning agents and accumulation of oils from handling and environmental exposure.

The combination tanning provides balanced performance characteristics, with the chrome tanning contributing softness, suppleness, and durability while the vegetable retanning adds structural integrity and the capacity for attractive aging. The leather adapts quickly to the wearer's foot shape, requiring minimal break-in compared to fully vegetable-tanned alternatives.

Applications

Natural Chromexcel is extensively used in heritage footwear construction, particularly for boots and shoes where character development is valued. The leather works well with various construction methods including Goodyear welting and handsewn techniques commonly employed by premium manufacturers.

Heritage boot makers appreciate Natural Chromexcel for applications requiring both durability and aesthetic appeal. The leather's combination of strength and flexibility makes it suitable for service boots, casual shoes, and moccasins where long-term wear and comfort are priorities. All footwear constructed with Chromexcel benefits from being 100% recraftable, allowing for repeated resoling to extend the product's lifespan.

The natural color variation between hides provides each piece with individual character from the outset, which further develops through the owner's use patterns. This makes Natural Chromexcel particularly popular for limited editions and specialty applications where uniqueness is valued.

Care and Maintenance

Natural Chromexcel requires minimal maintenance due to its oil and wax content from the hot-stuffing process. The manufacturer recommends Neatsfoot Oil for conditioning, as this matches the final treatment applied during production. Regular conditioning helps maintain the leather's flexibility and enhances the color development process.

The leather's natural oils and waxes provide inherent water resistance, though this should not be considered waterproofing. Routine care focuses on keeping the leather properly conditioned rather than intensive cleaning, as the patina development is part of the leather's intended character evolution.

References

"Chromexcel®". Horween Leather Co. March 23, 2010.

"Horween® Chromexcel". Oak Street Bootmakers. Retrieved September 5, 2025.

"Horween Chromexcel Leather Panel, Natural". Buckleguy.com. Retrieved September 5, 2025.

"The Attraction to Horween Chromexcel". Grantstone Shoes. Retrieved September 5, 2025.

"What Are Chromexcel Boots?". Nick's Boots. Retrieved September 5, 2025.