About

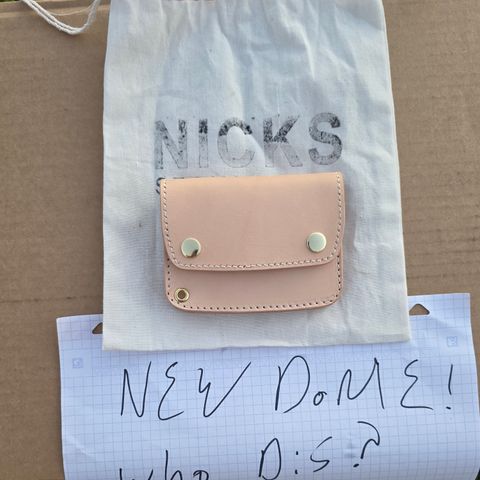

Natural Skirting is an undyed color variation of skirting leather produced by Wickett & Craig, an American vegetable tannery established in 1867. This completely vegetable tanned hide features a subtle natural buff color with a surface devoid of oils and wax, designed specifically for leatherworkers who prefer to customize the final appearance through their own dyeing and finishing processes.

About

Natural Skirting is an undyed color variation of skirting leather produced by Wickett & Craig, an American vegetable tannery established in 1867. This completely vegetable tanned hide features a subtle natural buff color with a surface devoid of oils and wax, designed specifically for leatherworkers who prefer to customize the final appearance through their own dyeing and finishing processes.

As a firm, heavy-duty leather traditionally used for saddles, holsters, and sheaths, natural skirting provides an unfinished canvas that allows crafters maximum control over the final product. The leather maintains the full-grain structure and tooling capabilities of dyed skirting leather while offering the versatility of an undyed base that readily accepts oils, dyes, and finishes.

Characteristics

Natural skirting leather exhibits a clean, undyed appearance resulting from the vegetable tanning process. The leather displays a natural buff color that is inherent to the tanning method rather than the result of applied dyes or finishes. This unfinished surface creates a blank canvas suitable for customization through additional treatments.

The leather features a firm texture with hard and rigid properties that provide minimal flexibility. This firm temper makes the material well-suited for applications requiring structural support and durability. Unlike finished skirting variants, the natural version maintains its unprocessed surface on both grain and flesh sides.

Manufacturing

Wickett & Craig produces natural skirting through complete vegetable tanning using traditional methods. The leather undergoes a drum dyeing process that imparts the characteristic firm temper while maintaining the natural color of the hide. Unlike English Bridle leather, skirting is not hot stuffed or waxed, leaving the surface receptive to additional treatments applied by the craftsperson.

The tanning process creates a full-grain natural hide with an unfinished surface that preserves the leather's ability to absorb oils and dyes. This manufacturing approach prioritizes the leather's working properties over aesthetic finish, providing leatherworkers with maximum flexibility in achieving their desired final appearance.

Working properties

Natural skirting demonstrates exceptional versatility for tooling, molding, and finishing applications. The unfinished surface allows the leather to accept dyes and oils exceptionally well, enabling crafters to create custom finishes tailored to specific projects. The firm texture supports detailed stamping and molding work while maintaining crisp impressions.

The leather displays characteristics similar to carving and tooling leathers, making it suitable for decorative leatherwork requiring precise detail. Despite arriving undyed from the tannery, the material readily takes on additional dye applications, allowing leatherworkers to achieve colors ranging from subtle earth tones to rich, saturated hues. The natural buff surface can also be oiled to develop darker patinas without applied dyes.

Applications

Traditional applications for natural skirting include saddles, holsters, and sheaths where both structural integrity and customization potential are valued. The leather's firm temper and heavy weight make it appropriate for equestrian gear that must withstand regular stress while allowing artisans to apply period-appropriate finishes.

Modern leatherworkers use natural skirting for belts, bags, and accessories where durability and aesthetic customization are priorities. The unfinished surface suits projects requiring specific color matching or aging characteristics that would be difficult to achieve with pre-dyed leather. The material also finds use in historical re-enactment armor and reproduction work where authentic finishing techniques are applied to create period-accurate appearances.

Specifications

Wickett & Craig offers natural skirting in weight ranges from eight to 14 oz, with custom splitting available down to two to three oz at no additional cost. Standard sides average 24 to 27 square feet, while backs measure 18 to 20 square feet. The leather is graded according to quality, with Standard, Utility, and Special grades indicating decreasing levels of natural imperfections in the hide.

The highest quality grades feature minimal surface imperfections, making them suitable for projects where both grain-side appearance and structural integrity are critical. All grades maintain the same working properties and ability to accept finishes, with grade primarily affecting the visual quality of the leather before treatment.

References

"SKIRTING". Wickett-Craig. Retrieved October 10, 2025.

"Wickett & Craig Carving Leather, Side, Natural Tooling". Buckleguy.com. Retrieved October 10, 2025.