About

Waxed Kudu is a specialty leather produced by Charles F. Stead using wild kudu antelope hides from Southern Africa. The leather combines the tannery's proprietary Janus tannage with full wax impregnation, creating a material valued for its natural character markings and combination of softness with strength.

About

Waxed Kudu is a specialty leather produced by Charles F. Stead using wild kudu antelope hides from Southern Africa. The leather combines the tannery's proprietary Janus tannage with full wax impregnation, creating a material valued for its natural character markings and combination of softness with strength.

The leather is sourced from seasonal culls of kudu populations living in the Southern African bush. Each hide retains natural scars, scratches, and grain variations from the animal's wild environment, resulting in unique character that varies significantly between skins. The wax finish highlights these natural imperfections while providing protection and distinctive pull-up characteristics.

Waxed kudu is used by heritage footwear makers including Viberg, Meermin, and Oak Street Bootmakers for boots requiring both durability and distinctive patina development. The leather's 2mm thickness and inherent suppleness make it suitable for welted construction while maintaining comfort during wear.

Material origin

Kudu hides are obtained from wild antelope populations native to Southern Africa. The animals live in bush environments where natural obstacles create the cuts, scars, and blemishes that characterize the leather. Skins are sourced through seasonal licensed culls conducted to manage herd populations.

The undomesticated nature of the source animals produces hides with significant variation in grain patterns and natural markings compared to leather from farmed livestock. These characteristics are preserved and emphasized during tanning rather than corrected or concealed.

Tanning process

Charles F. Stead applies its Janus tannage method to kudu hides, a process originally developed to enhance the natural mellowness of calfskin. The fiber structure of kudu leather responds to this tannage by producing soft suede on the reverse side while maintaining high strength throughout the hide.

Following tanning, a full wax impregnation is applied to the grain surface. This treatment makes a feature of the natural grain blemishes rather than minimizing them, creating the leather's characteristic appearance. The wax provides additional protection against water and wear while contributing to the material's pull-up effect, where leather temporarily lightens in color when bent or creased.

The chrome tanning process precedes the specialized re-tannage. Hides arrive at the facility pre-treated with either mineral or plant-based processes before undergoing the company's distinctive finishing methods.

Characteristics

Waxed kudu demonstrates what manufacturers describe as a mellow temper, combining pliability with resistance to tearing. The leather measures 1.6-2.2mm in thickness and weighs 4.5-5.5 ounces per square foot. Individual skins range from 10-22 square feet, with average dimensions of 13-15 square feet.

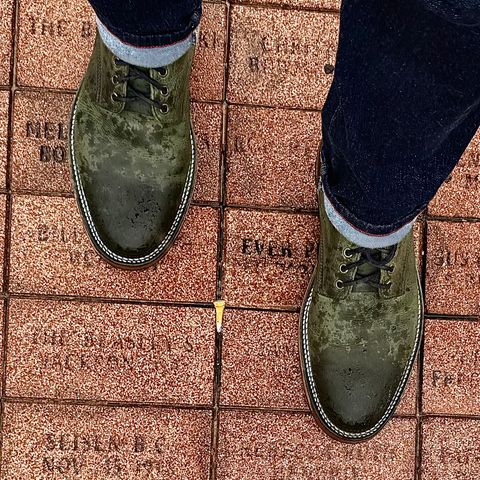

The grain surface features a nubuck texture with wax treatment, while the reverse presents as soft suede. This dual-sided structure results from the Janus tannage method. The leather exhibits pull-up characteristics, temporarily showing lighter tones in areas of flexion before returning to base color.

Natural markings from the animal's life in wild environments appear throughout each hide. These include scratches from thorny vegetation, scars from encounters with predators or other animals, and variations in grain tightness. The wax finish emphasizes rather than conceals these features, contributing to each piece's distinct appearance.

The material develops patina through use, with high-wear areas showing accelerated color change and surface texture evolution. The wax coating responds to handling and environmental exposure by developing depth and variation in appearance over time. Recovery against mild scratches occurs through the redistribution of wax on the surface when rubbed.

Available colors

Charles F. Stead produces waxed kudu in an extensive range of colorways including Flint, Autumn Spice, Bitter Chocolate, Brick, Camel Hair, Cloudburst, Dark Burgundy, Forest, Gaucho, Military Green, Nighthawk, and Rosewood, among others.

Character markings and natural variations appear more prominently in lighter colorways due to the contrast between wax-saturated areas and exposed grain. Darker shades integrate these features more subtly while maintaining the textural variation that defines the leather.

Color naming may vary between distributors and manufacturers. Some suppliers list the leather under variations of "Kudu Waxy" or "Waxy Kudu" rather than "Waxed Kudu," though these refer to the same product line.

Care and maintenance

Regular maintenance prevents the leather from drying out while preserving its wax finish. Manufacturers recommend periodic applications of dubbin wax, specifically citing Famaco Dubbin Wax as appropriate for waxed kudu. For lighter protection needs, Famaco Renovateur provides conditioning without heavy wax buildup.

Basic cleaning requires only a horsehair brush and slightly damp cloth for most situations. The natural waxiness of the leather reduces maintenance frequency compared to other leather types. When deeper conditioning becomes necessary, products should be applied with a dedicated horsehair brush using deliberate strokes to work the treatment into the surface.

Waterproofing sprays designed for nubuck can supplement the existing wax protection. The leather does not require polishing compounds or high-shine treatments, as the wax finish produces a matte appearance rather than a glossy surface. Natural leather balms and conditioners with minimal chemical additives work well with the material's existing finish.

The frequency of conditioning depends on climate and usage patterns. The inherent wax content provides baseline protection that extends time between treatments compared to non-waxed leathers of similar weight and construction.

References

"Waxed Kudu". Charles F Stead and Co Ltd. Retrieved September 30, 2025.

"C.F. Stead Waxy Kudu Leather". The Tannery Row. Retrieved September 30, 2025.

"Service Boots Nutmeg and Stone Waxed Kudu". Viberg. Retrieved September 30, 2025.

"Waxy Kudu". Meermin Shoes. Retrieved September 30, 2025.