Nicks Handmade Boots

MakerAbout

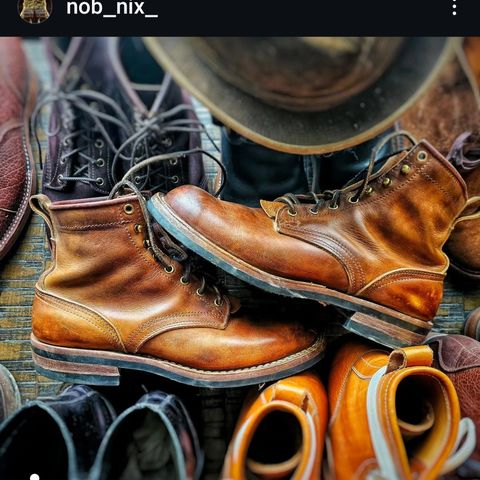

Nicks Handmade Boots is an American boot manufacturer founded in 1964 by Nikolai Blahuczyn in Spokane, Washington. The company specializes in handmade work boots, fire boots, heritage boots, western boots, and outdoor boots using stitchdown construction and full-grain leather. Since 2013, Nicks has been owned by Steve Mowe, with day-to-day operations managed by his son Shuyler Mowe since 2020.

About

Nicks Handmade Boots is an American boot manufacturer founded in 1964 by Nikolai Blahuczyn in Spokane, Washington. The company specializes in handmade work boots, fire boots, heritage boots, western boots, and outdoor boots using stitchdown construction and full-grain leather. Since 2013, Nicks has been owned by Steve Mowe, with day-to-day operations managed by his son Shuyler Mowe since 2020.

The company operates from its facility at 6510 E Sprague Ave in Spokane, continuing a 60-year tradition of Pacific Northwest boot making. Nicks is known for using primarily stitchdown construction rather than Goodyear welting, hand-selecting leather to create only 1.75-2 pairs per hide compared to competitors' 5-6 pairs, and offering extensive customization options including widths from AA to FFFF.

History

Nicks Handmade Boots was founded in 1964 by Nikolai Blahuczyn, also known as "the Original Nick." Blahuczyn was born in 1922, either in Russia outside Moscow or in Ukraine of Russian descent. He learned shoemaking from his parents at age nine in 1930, as both were shoemakers. The family immigrated to the United States through New York and lived in Minnesota and North Dakota before settling in Washington state.

Before establishing his own company, Blahuczyn worked for White's Boots in Spokane. After founding Nicks, he operated the business for nearly 50 years until selling it in 2013 to Steve Mowe. Steve's son Shuyler joined the company in 2020 and now manages day-to-day operations. The company moved to its current location at 6510 E Sprague Ave in Spokane in 2015.

Construction methods

Nicks uses primarily stitchdown construction instead of the more common Goodyear welt method. According to the company, stitchdown construction provides a stronger boot than other welting methods including Goodyear welt. The process involves hand-stitching all layers together without an exposed welt, creating a direct connection between the upper and sole.

The company employs the McKay lockstitch method, which provides a barrier against water and dirt infiltration. While Nicks offers a hand-welting option, their standard construction method remains stitchdown. The labor-intensive process includes hand-welting, hand-lasting, and double-row stitching, with each boot requiring extensive hand work throughout production.

Materials and quality

Nicks uses exclusively full-grain leather, selecting specific sections of each hide. The company creates 1.75-2 pairs of boots per hide compared to competitors who typically produce 5-6 pairs per hide, resulting in higher material costs but higher leather yield per hide. All leather is sourced from American suppliers.

The company offers various leather types including Horween waxed flesh leather and weatherproof roughout options. Leather thickness for work boots measures 7-8 ounces (2.8-3.2mm), approximately three times thicker than typical dress shoe leather. According to the company, properly maintained full-grain leather boots can last 10-100 years and will mold to the wearer's feet over time.

Product range

Nicks specializes in work boots, fire boots, heritage boots, western boots, and outdoor boots. The company's fire boots carry NFPA (National Fire Protection Association) certification for professional firefighting use.

The company produces numerous boot models designed for different applications and preferences. Popular heritage models include the Ranger, known for its robust construction with 80 nails and seven layers of leather sole. The Robert boot is constructed on the company's 55 last with a Cuban/dogger heel design. The Urban Logger features a 2+ inch logger heel for outdoor work applications. The Americana represents the company's heritage boot line with classic styling.

For detailed specifications and features of individual models, see the dedicated articles for each boot style.

Manufacturing and customization

All Nicks boots are manufactured by hand at the company's Spokane, Washington facility. The company offers boots in widths ranging from AA to FFFF and provides extensive customization options including toe shape variations, different eyelet and hook configurations, and edge color choices.

The handmade construction process allows for boots to be resoled and rebuilt multiple times, supporting lifetime durability when properly maintained. Each boot undergoes the complete hand-construction process at the single Washington location, maintaining direct quality control over all production.

References

"About Nicks". Nicks Handmade Boots Official Website. Publication date unavailable. Retrieved August 29, 2025.

"Nicks Handmade Boots Since 1964". Seattle Fashion Collective. December 20, 2021. Retrieved August 29, 2025.

"Nicks Handmade Boots Review: The Nicks Robert Boot". Almost Vintage Style. September 24, 2020. Retrieved August 29, 2025.