About

Horween Black Waxed Flesh is a distinctive roughout leather produced by Horween Leather Company that presents the flesh side of the hide as the exterior surface while maintaining the grain side as the interior. This black-colored variant of Waxed Flesh leather combines the unique texture and character of reversed leather construction with intensive wax treatment that creates a distinctive surface appearance and enhanced weather resistance.

About

Horween Black Waxed Flesh is a distinctive roughout leather produced by Horween Leather Company that presents the flesh side of the hide as the exterior surface while maintaining the grain side as the interior. This black-colored variant of Waxed Flesh leather combines the unique texture and character of reversed leather construction with intensive wax treatment that creates a distinctive surface appearance and enhanced weather resistance.

The leather represents a departure from traditional leather finishing, where the normally hidden flesh side becomes the featured surface, revealing the natural fiber structure and providing a nubuck-like texture that develops character through use. The black coloration and heavy wax treatment create a leather that begins with a relatively uniform appearance but evolves dramatically over time, developing lighter patches and color variation that reflect individual wear patterns.

Tanning process

Horween Black Waxed Flesh undergoes a combination tanning process similar to other Horween leathers, beginning with chrome tanning followed by vegetable re-tanning using natural bark extracts. The distinctive characteristic of waxed flesh comes from the subsequent wax treatment, where the flesh side of the leather receives intensive applications of specialized waxes designed to penetrate the open fiber structure and create the characteristic surface texture.

The black coloration is achieved through careful dye application that penetrates the leather structure while allowing the natural variation in the flesh side to remain visible. The wax treatment follows the dyeing process, with multiple applications ensuring complete saturation of the exposed fiber structure. This process creates a leather that initially appears almost uniformly black but contains the potential for dramatic color evolution as the wax redistributes through use.

The flesh side preparation requires specific techniques to achieve consistent texture while maintaining the structural integrity necessary for footwear and other applications. Each hide receives individual attention to ensure the wax penetration and surface preparation meet Horween's quality standards.

Characteristics and properties

Black Waxed Flesh exhibits unique properties that distinguish it from both traditional grain-out leathers and conventional roughout materials. The flesh side surface provides enhanced traction and grip compared to smooth grain surfaces, while the heavy wax content offers superior water resistance and weather protection. The material typically measures 4-6 ounces in weight, providing substantial structure while maintaining flexibility.

The leather demonstrates exceptional scuff resistance, with minor surface damage often healing through the redistribution of wax content with heat and pressure. This self-healing property makes Black Waxed Flesh particularly suitable for applications where surface durability is paramount. The wax content also provides natural conditioning that helps prevent the flesh side from becoming brittle or cracking under stress.

The material exhibits moderate stretch characteristics, with the flesh side structure allowing for accommodation of foot movement in footwear applications while maintaining shape retention over time. The black coloration provides excellent hide coverage while serving as a foundation for the distinctive patina development that makes waxed flesh leather particularly prized among enthusiasts.

Color and appearance

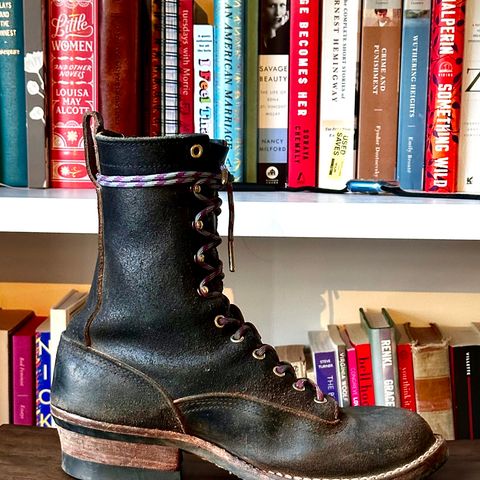

Fresh Black Waxed Flesh presents as a deep, rich black with subtle variation created by the natural texture of the flesh side surface. The heavy wax content initially creates a relatively uniform appearance with a matte to low-luster finish, though the underlying fiber structure remains visible as subtle texture variations across the surface.

The leather's appearance transforms dramatically through use, with handling and wear causing the wax to redistribute and revealing lighter underlying colors. This process typically begins within days of use, with high-contact areas showing the most dramatic color evolution. The black surface gradually develops patches of brown, gray, and tan tones as the wax migrates, creating a unique patina pattern that reflects the individual item's usage and wear characteristics.

The flesh side texture contributes to the visual interest, with the natural fiber structure creating depth and shadow that enhances the color evolution process. This combination of texture and color change results in leather goods that develop distinctive individual character over time.

Aging and patina development

Black Waxed Flesh undergoes some of the most dramatic patina development of any leather type, with the transformation process beginning almost immediately upon use. The initial black appearance gives way to complex color patterns as wax redistributes from high-wear areas to protected zones, revealing the natural leather colors beneath the surface treatment.

The patina development occurs through both mechanical action and thermal effects, with body heat and friction causing wax migration while handling oils contribute to color evolution. High-contact areas typically lighten to brown or tan tones within weeks of use, while creases and protected areas may retain black coloration for extended periods, creating high-contrast patterns that emphasize construction details and wear patterns.

The rate of patina development can be influenced by use conditions, with more aggressive wear accelerating the color evolution while gentle use allows for more gradual transformation. The process is largely irreversible, making each piece of Black Waxed Flesh unique in its development pattern and final appearance.

Applications

Black Waxed Flesh serves primarily in work boot and outdoor footwear applications where durability, weather resistance, and distinctive appearance converge. The leather's properties make it particularly suitable for boots intended for rough use, including construction, outdoor recreation, and motorcycle riding where the enhanced surface durability provides practical benefits.

Notable manufacturers utilizing Black Waxed Flesh include Viberg, White's Boots, and Nick's Boots, who leverage the leather's unique properties in premium work boot construction. The material works particularly well with traditional construction methods including stitchdown and Norwegian welting, where the robust leather characteristics complement heavy-duty construction approaches.

The leather also appears in leather goods applications including bags, belts, and wallets, though footwear remains the primary use due to the dramatic patina development that occurs with regular handling. The distinctive appearance evolution makes these items particularly appealing to users who appreciate personalized aging characteristics.

Care and maintenance

Black Waxed Flesh requires minimal care compared to many leather types, with the heavy wax content providing natural protection against moisture and environmental damage. The flesh side surface benefits from occasional brushing with stiff-bristled brushes to maintain texture and remove surface debris, while avoiding traditional leather conditioners that can interfere with the wax treatment.

The patina development process is largely self-managing, with the wax redistribution occurring naturally through use. Users seeking to accelerate or direct the patina development can apply controlled heat and pressure to encourage wax migration, though this process should be approached carefully to avoid damage to the leather structure.

Water exposure should be managed carefully, as excessive moisture can affect the wax distribution and potentially alter the patina development pattern. The leather should be allowed to dry naturally if wet, with the wax content providing substantial protection against water damage when properly maintained.

References

"Waxed Flesh Leather: Properties and Care". Viberg Boot. Retrieved September 6, 2025.

"Understanding Roughout and Waxed Flesh Leathers". White's Boots. Retrieved September 6, 2025.

"The Art of Waxed Flesh: Horween's Unique Leather". Horween Leather Co. July 15, 2019.

"Waxed Flesh Patina Development and Care". Nick's Boots. Retrieved September 6, 2025.

"Black Waxed Flesh in Work Boot Construction". Red Wing Heritage. Retrieved September 6, 2025.

"Flesh Side Out: The Appeal of Roughout Leathers". LeatherWorker.net. Retrieved September 6, 2025.

"Waxed Flesh Leather Applications and Properties". Baker Shoe. Retrieved September 6, 2025.

"Waxed Flesh Leather Evolution and Character Development". Horween Leather Co. March 12, 2020.

"Working with Waxed Flesh: A Manufacturer's Perspective". Drew's Boots. Retrieved September 6, 2025.