Viberg

MakerAbout

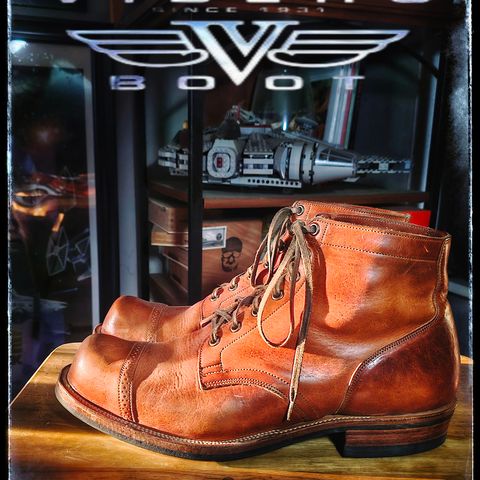

Viberg is a Canadian footwear manufacturer founded in 1931 by Edwin Viberg, a Swedish immigrant who established the company during the Great Depression. Based in Victoria, British Columbia, the third-generation family business produces heritage work boots using traditional construction methods including stitchdown and Goodyear welt techniques.

About

Viberg is a Canadian footwear manufacturer founded in 1931 by Edwin Viberg, a Swedish immigrant who established the company during the Great Depression. Based in Victoria, British Columbia, the third-generation family business produces heritage work boots using traditional construction methods including stitchdown and Goodyear welt techniques.

The company operates from its original factory in Victoria, where over 200 individual steps are involved in producing each pair of boots. Edwin Viberg's son Glen has worked on the factory floor for 40 years, personally involved in virtually every production run, while Glen's son Brett has expanded the brand into contemporary heritage fashion markets. Viberg specializes in the Service Boot, their foundational product dating back to the 1930s, available in multiple lasts and various materials with pricing ranging from $640 to $2,080 for Shell Cordovan versions.

History

Edwin Viberg immigrated to Canada from Sweden in 1907, initially settling on farmland in Saskatchewan where he made leather harnesses for work horses and belting for machinery. During the Great Depression in 1931, he apprenticed with a British shoemaker and founded Viberg Boot Manufacturing Ltd. Edwin proved to be an effective merchant, traveling around the Prairie provinces selling boots to workers.

When the logging industry expanded in the 1950s and 1960s, Edwin relocated his business westward to follow the work opportunities in the Pacific Northwest. The company settled permanently in Victoria, British Columbia in the early 1970s, where the factory continues to operate today.

The business remains in the Viberg family through its third generation of ownership and operation. Edwin's son Glen Viberg has worked on the factory floor for the past 40 years, rotating through each station and personally adding finishing touches to every production run. Glen's son Brett Viberg has reimagined heritage-based fashion by combining institutional quality with vintage styles for contemporary markets.

Manufacturing

All Viberg boots are manufactured from start to finish at the company's Victoria, British Columbia workshop by a small team of craftspeople. The factory operates from a building where the ceiling is draped with national flags and floors hum with machinery, while skilled workers collaborate on boot production.

The manufacturing process involves over 200 individual steps to produce a pair of Viberg work boots. Glen Viberg remains personally involved on the factory floor, working on virtually every station for each production run and adding finishing touches between machinery operations.

Materials are sourced globally for production, including outsoles from Italy, leathers from the United States and Vietnam, and brass nails from Japan and the United Kingdom. Viberg is the only global manufacturer using solid brass nails, tacks, and staples, which are custom-made in Japan specifically for their construction requirements.

Construction methods

Stitchdown construction

Viberg implemented stitchdown construction in the 1970s as their primary building method, executed largely by hand. The process begins with heavy-weight 5 to 5.5-millimeter leather insoles paired with solid leather heel and toe stiffeners, creating a 100% natural chassis that conforms to foot shape over time.

The hand-lasting process uses side lasting pliers, hammers, and solid brass tacks. Workers skive the upper leather by hand, then cut and turn the vamp outwards to stitch it onto the solid leather midsole. This technique requires two rows of stitching placed side-by-side during the outsole attachment, with no margin for error during the process.

Stitchdown construction produces fully resoleable and recraftable boots capable of lasting 10 to 15 years with proper care. The heavy-weight leather insoles, measuring 5.2 to 5.5 millimeters in thickness, provide the strongest hold and durability for extended wear periods.

Channelled insole Goodyear welt construction

Viberg also employs channelled insole Goodyear welt construction, a traditional method dating back to the 1860s that uses thick solid leather insoles. The insole thickness measures approximately 2.5 times heavier than gemmed construction alternatives, providing enhanced structural support.

This construction method creates an almost watertight boot with maximum foot comfort and longevity. The design provides better structural support as the shoe flexes with bodyweight during wear, allowing the boot to adapt to the wearer's gait and movement patterns over time.

Product lines

Viberg's foundational product is the Service Boot, originally created by Edwin Viberg in the 1930s as a work boot for farmers. This ankle derby boot has become one of the company's most versatile patterns, available across multiple lasts and pricing from $1,040 for standard models to $2,080 for Shell Cordovan versions.

The company produces various other models including the Chelsea boot and work-specific designs. For detailed specifications, pricing, and available materials for each model, see the dedicated product articles.

Lasts and sizing

Viberg uses a proprietary sizing system where customers generally size down one full size from their US Boot or Brannock Size, with variations depending on the specific last. The company produces boots on three primary toe shape categories: Almond Toe lasts with elongated symmetrical toes, Round Toe lasts with wider half-circle shapes, and Anatomical Bump Toe lasts that follow natural foot contours. Specific sizing recommendations and last characteristics are detailed in individual product articles.

Materials

Viberg prioritizes leather soles in their construction because they "last longer and perform better" than synthetic alternatives. The company sources heavy-weight leather insoles measuring 5.2 to 5.5 millimeters in thickness, designed to provide the strongest hold and enable 10 to 15 years of wear capability.

The company maintains exclusive use of solid brass nails, tacks, and staples that are custom-made in Japan, making Viberg the only global manufacturer to employ solid brass components throughout their construction process. These brass components are sourced from both Japan and the United Kingdom to meet their specific requirements.

Materials are sourced from multiple countries to meet Viberg's quality standards, including outsoles from Italy, various leather types from the United States and Vietnam, and specialized hardware components from Japan and the United Kingdom. This global sourcing approach ensures access to specialized materials for heritage boot construction.

References

"The Story of Viberg Boot". Viberg Boot Company. Retrieved August 29, 2025.

"Edwin Viberg, Entrepreneur". Viberg Journal. Retrieved August 29, 2025.

Sharp Magazine. "Inside the Viberg Boot Factory in Victoria, BC". June 15, 2016.

"An Exploration of Stitchdown Construction". Viberg Journal. Retrieved August 29, 2025.

"Channelled Insole Goodyear Welt Construction". Viberg Journal. Retrieved August 29, 2025.

"Service Boot Collection". Viberg Boot Company. Retrieved August 29, 2025.

"Last Guide". Viberg Boot Company. Retrieved August 29, 2025.

"Building a Heritage Brand: Case Study with Viberg Boot". Shopify Blog. Retrieved August 29, 2025.